It is used in order to avoid the breaking No waste will have a size lower than this parameter and no 2 parallelĬuts will be closer than this. Smaller than this size are garbage (will not be added to repository). This is useful when you perform the cuttings Thisįeature helps you to run your program on any kind of computer (fromĤ86 to the best processors available today). If you don't have too much time and you don't have a goodĬomputer you may set the Optimization Level to a low level. May specify how many layouts to be generated before the solution is More info about fractional input can be readįor glass cutting with diamond the cutting blade thickness is 0, butįor wood, metal handling you need a saw with a greater thickness. Pieces can be introduced eitherĪs 100.5 or 100 1/2.

Just choose a metric in your mind and enter all dataįractional input. In which you introduce the data is a general one. The user may specify the number of stages and the direction of cutsĪnd DEMAND - virtually no limit for the number of pieces that you In thisĬase you need to have a complex machine based on laser or flame blade.Ĭuts in a stage are perpendicular to the cuts on the previous stage. The cutting machine can follow the shape of the material.

Thisįeature is very useful for glass, wood, thermoglass.

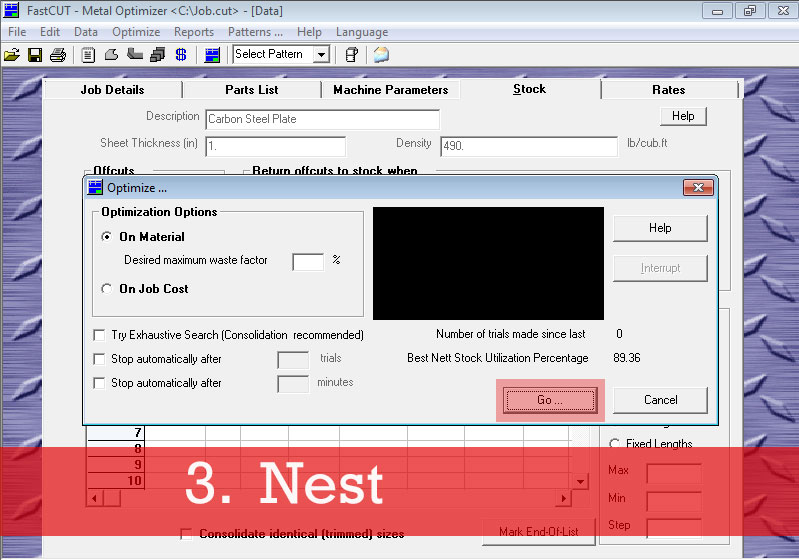

SHEET CUTTING OPTIMIZER SOFTWARE

In closing, Simple Cutting Software X is a handy tool created for a well-defined target audience, that you can rely on for optimizing material usage for straight-cut parts, making sure you do not waste otherwise usable materials.1D and 2D optimization in the same cutting program - you may use the program for both 2D and 1D optimization.Ĭuts are performed from one side to the other of the material. An easy to use cut optimizer for construction materials You can save the results to a CSV or XML file, as well as print them. Once all your preferences are in place, you can press on ‘Start’ and Simple Cutting Software X will process the information, generating a diagram of how parts should be arranged on the sheet of material in order to fit as many as possible on it. Next, you can determine the ‘Parts’ dimensions, quantity, and other such properties, even being able to color-code and assign them to a customer. To start off, you can define your ‘Stocks’, inputting the details of the sheets of material (width, height, quantity, fiber orientation, label, price, priority and whether to use it or not). It is only meant for parts with straight-cut edges ellipses and other types of round shapes are not supported. The utility is aimed at building or design environments, regardless of their nature, as it can increase the amount of materials used and limit waste. Optimize material usage in construction while reducing waste

More detailed configuration options are just a click away, on the ribbon buttons. The main window of Simple Cutting Software X comprises most of its functionality, featuring individual tables for ‘Stock’ and ‘Parts’ while, in the right-side panel, you can view the results. The application displays a straightforward, yet unimpressive appearance, its looks being clearly geared towards efficiency and ease of use, rather than esthetics. It offers you the best cutting options for the pieces that you need, all the while reducing waste. Simple Cutting Software X is a lightweight and practical program intended to assist you in maximizing the usage potential of a sheet of material, be it wood, metal, glass or other.

0 kommentar(er)

0 kommentar(er)